To fit the intercooler, the intake hose needs to be trimmed quite a bit so that the attached tube with the sensors is almost horizontally level. The metal disc with the rubber hose to the solenoid valve should be rotated by 90° to avoid interference with the intercooler. The sensor wires for that intake tube are too short. You need to cut the wrap from the wiring harness to get some extra cable length. If you have to use a knife or a scalpell to trim the hoses I find it easier to cut along a hose clamp.

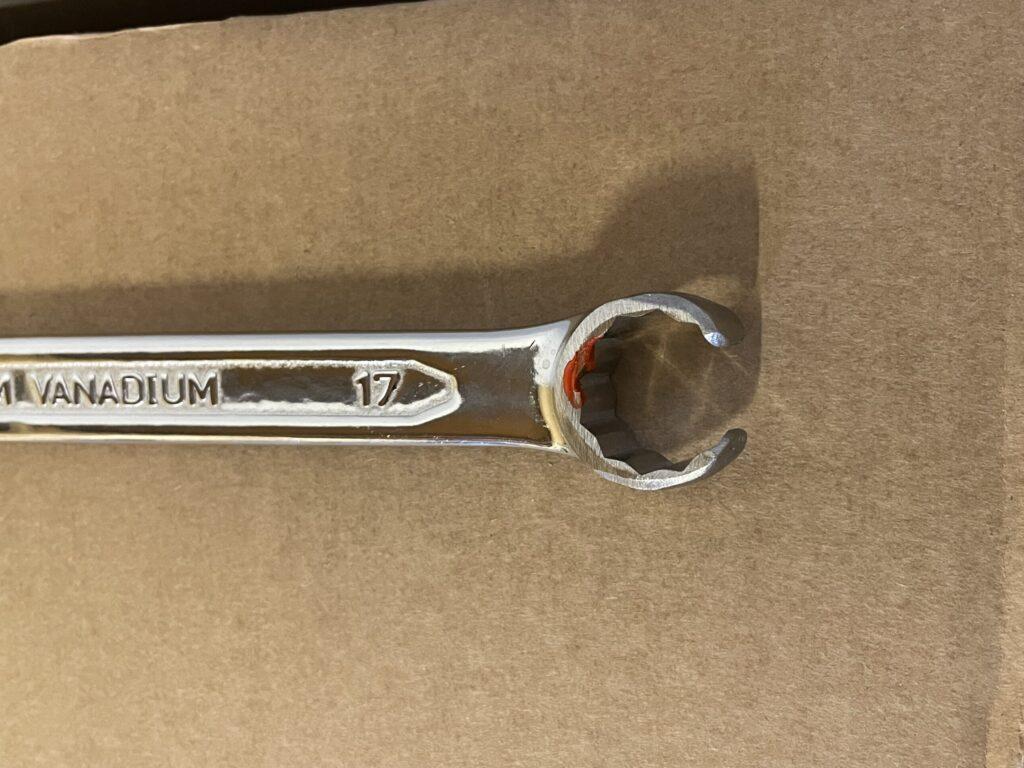

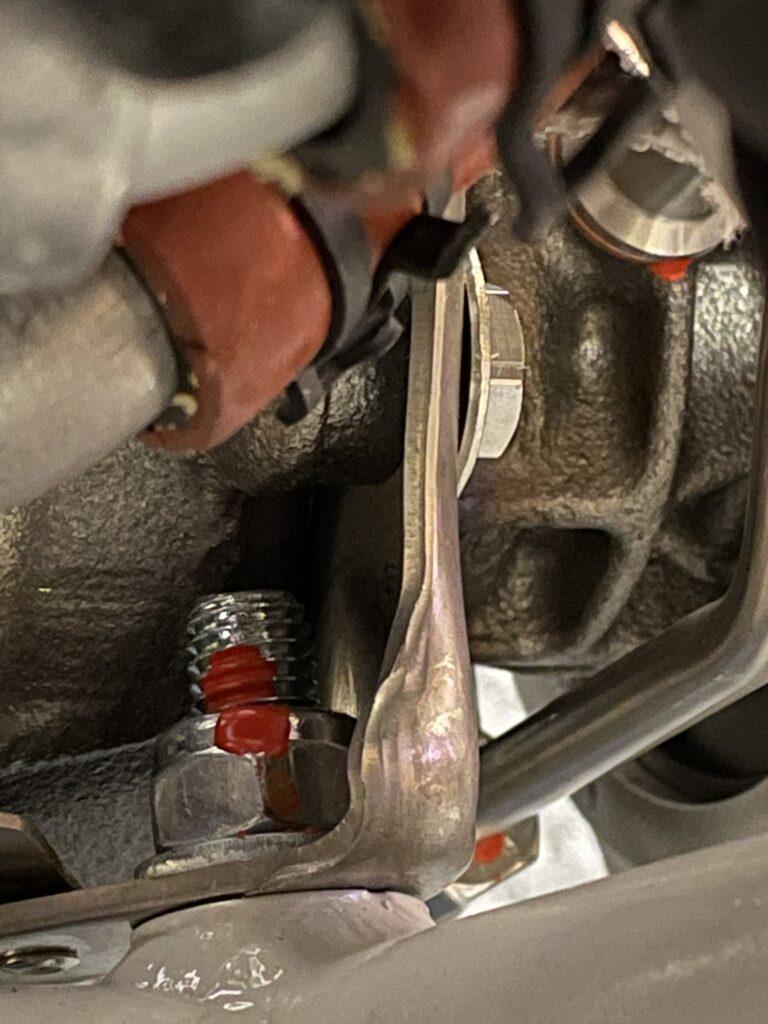

Inserting the engine bolts is not very difficult except the lower right bolt. This bolt needs to be shortened to 125mm to not touch the turbo charger. The next challenge is to tighten this bolt to 38Nm (28ft.lb) where it’s almost impossible to reach the nut. I had to fabricate a special 17mm wrench to reach the nut and to be able to get it out after torqueing it to spec. There is still a small gap between the bolt and the turbo but I would shorten the bolt to 123mm next time.

Unboxing the engine takes some time, Rotax did a good job in securing the engine in it’s crate.